Perfecting Microphone Comparison Science at Harman Labs

Clockwise from top left: Harman researchers Omid Khonsaripour and Dr. Sean Olive, ATK founder Alex Oana and Harman researcher Todd Welti, Harman engineer Chris Hagen, Todd Welti. Lower left: Dr. Olive.

Prior to our work with Harman, Audio Test Kitchen achieved 95% realism in the sound of reamplified acoustic sources, a key factor that differentiates Audio Test Kitchen from any equipment comparisons done in the past. Closing the gap on the final 5% would make all the difference and require the assistance of the world’s top audio research scientists and their lab.

ATK’s Research Goal at Harman:

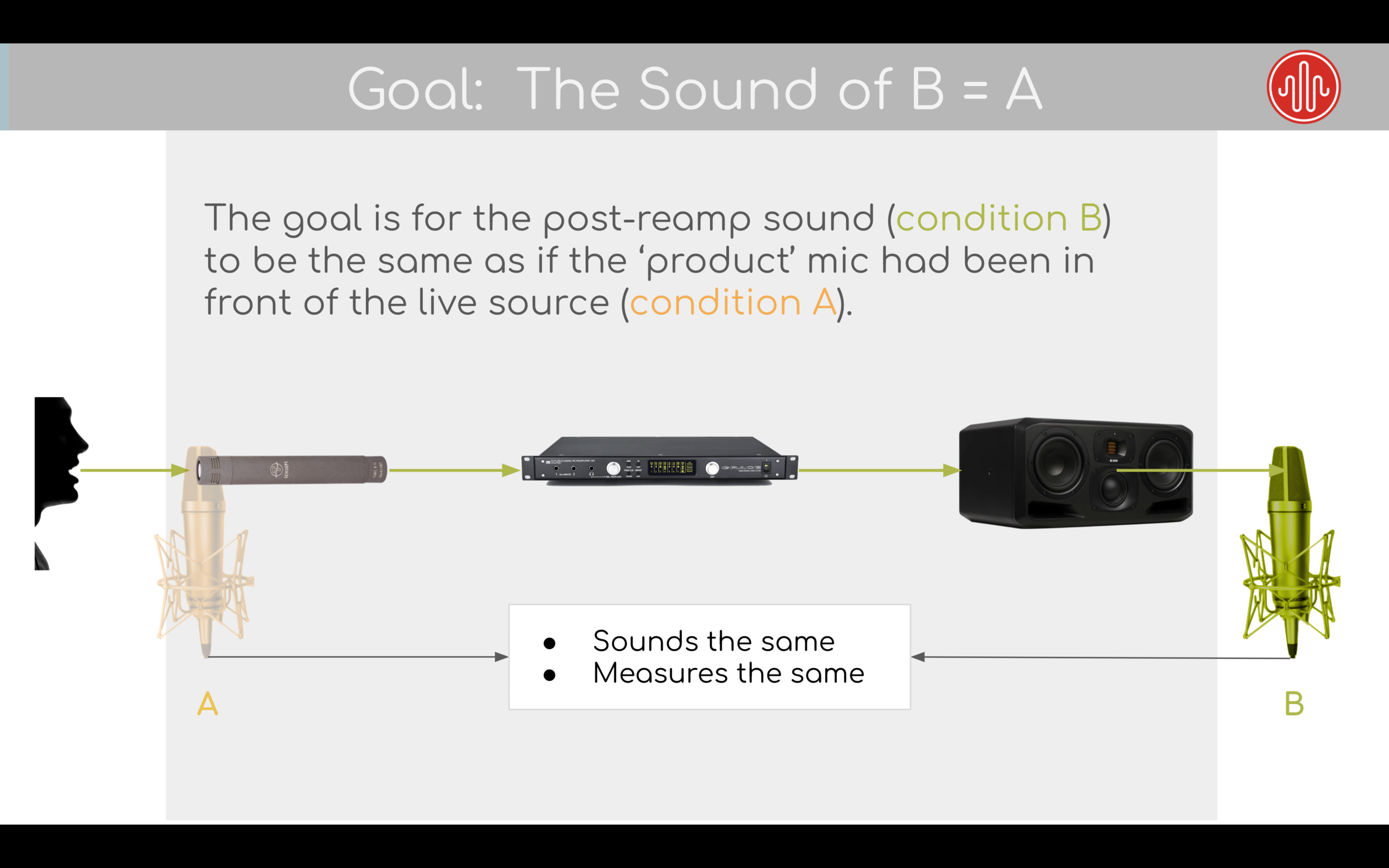

To make the reamped source sound identical to the live acoustic source

in order to…

Eliminate the variable of human performance from microphone comparisons. Why? So that the only audible differences when switching between microphones on the Audio Test Kitchen app are the differences between the microphones. Other elements — source and signal chain — become non-variables, making unbiased microphone comparisons possible

Ensure the reamplified source sounds identical to the original live source. Why? So that the microphone characteristics users hear in their Audio Test Kitchen mic tests are the same as real-world recordings

How is success measured/judged?

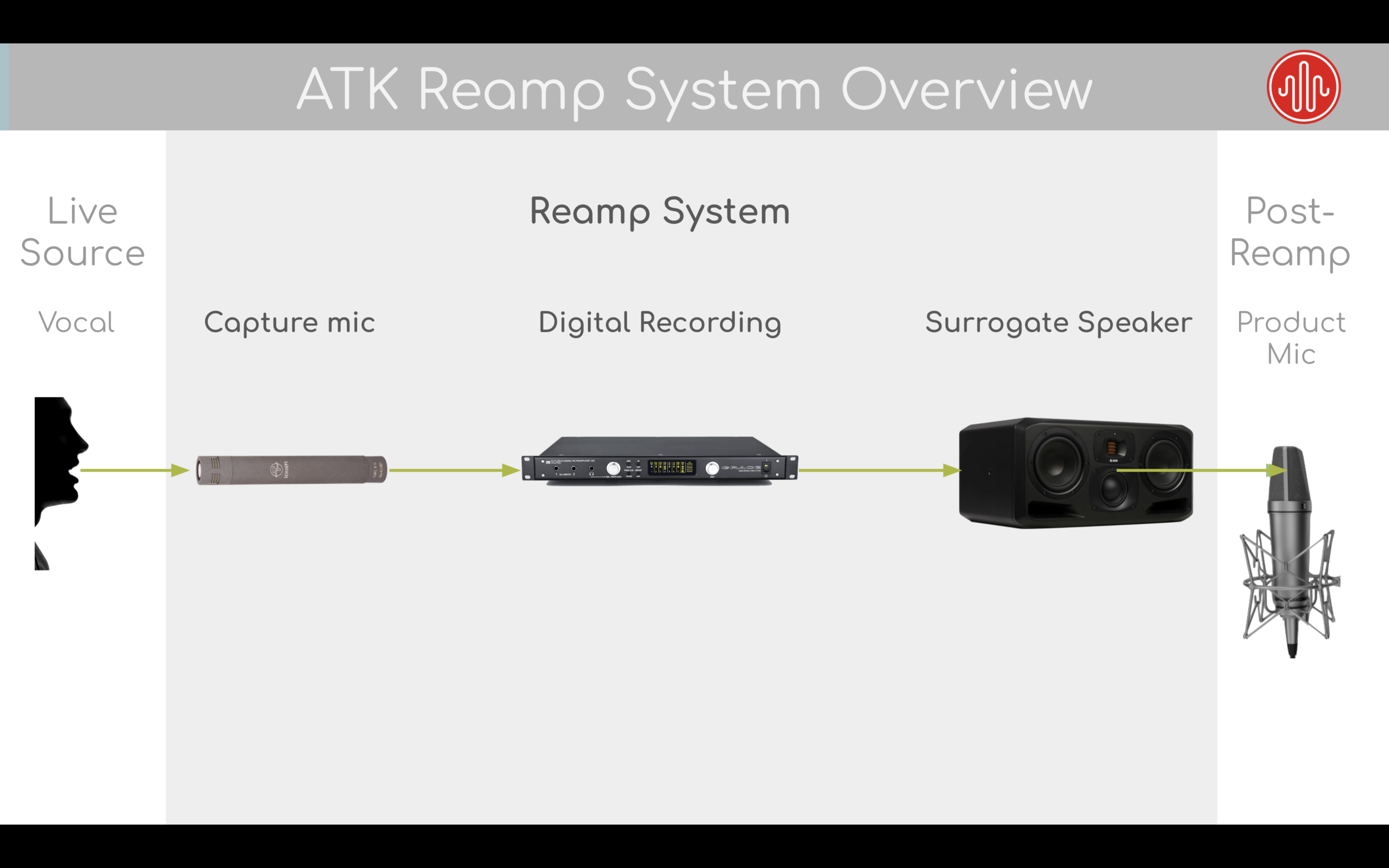

A live acoustic performance — vocal or acoustic guitar — captured live by an interchangeable ‘product' mic (Shure, Telefunken, Manley, Neumann, etc.) would sound the same as that performance captured by the reamplification system: ‘bottling' or ‘capture’ microphone plus ’surrogate’ speaker, as illustrated by the slides below:

Variables

CAPTURE

Signal chain: microphone, cable, preamp, AtoD converter

‘Capture’ mic position: position relative to the acoustic source

REAMP

Signal chain: DtoA converter, cable, speaker

Product microphone position: position relative to the reamp speaker

In order to select every element (variable) of the signal chain (cable, preamp, analog to digital converters…) used for capturing and reamplifying acoustic sources, one must isolate each of those elements and test them one at a time:

Which capture microphone to ‘bottle’ the acoustic source?

Positioned where relative to the source?

Reproduced ('reamped’) by what ‘surrogate’ speaker?

At what position (‘sweet spot’) relative to the speaker?

In the end answering this: What mic Which speaker and Where?

In traditional recording studios, acoustic artifacts distort the environment required to systematically test one variable at a time. We did as much refinement as possible of the signal chain element choices (capture microphones and reamp speakers) by ear..

During R&D, we were hearing artifacts in the recording studios we knew were a product of the acoustic space and not artifacts of the microphones, therefore knew we couldn’t refine our choices any further without eliminating the acoustics variable. — Alex Oana, Creator/Founder, Audio Test Kitchen

Always driven by curiosity and knowledge, Dr. Sean Olive was intrigued by the opportunity to learn about so many microphones.

Harman helped ATK close the gap to solving these problems in five ways:

FIRST

Harman’s anechoic chamber is an artifact-free environment which allowed ATK to validate our microphone and speakers choices we had made in our R&D up until this stage, as well as test additional options. This validation process was done in Harman’s chamber by ATK, by ear, manually and then with the assistance a Dynamount X1-R microphone positioning robot.

SECOND

Once the signal chain (reamp chain) elements were established, further refinement of A) the positioning of capture mic relative to the acoustic source, and B) the reamp speaker positions relative to the ‘product' microphone were established.

This process was done in Harman’s chamber by ATK, both manually and through use of the Dynamount mic positioning robot. We primarily let our ears be our guide, but also used some realtime spectral analysis to indicate when our reamp capture mic positioning most closely matched the original source.

THIRD

Once the signal chain elements and their positions were refined as much as possible (Schoeps into ADAM at a specific position, and DPA into ATC at a specific position) adjusting only equipment selection and positioning refinement, we could still hear a slight difference between the reamped source and the live source. That’s where Harman scientist Todd Welti came in: analyze the differences and correct for them. In the end, Todd generated an IR (Impulse Response) filter that corrects for frequency spectrum and phase differences compared to the original source. To test the success of the filter, we applied the IR to the output of our digital audio workstation (Pro Tools), altering the signal to the input of the reamp speaker so that in effect the response of the reamp speaker corrected for all deviations caused by the elements of the reamp system.

The details:

We provided before/after (live/reamp) audio files of acoustic sources – singing, talking, acoustic guitar – and sine wave sweeps and pink noise for Todd to analyze. His analysis showed the following

Our by-ear work had brought us within a very small difference margin (high fives, @Fluff!)

The differences were consistent, no matter which source

The differences were consistent, no matter which ‘product mic’ we captured

When we tested Todd’s IR correction by ear, it sounded amazing. In a blind test, there was no way one would be able to identify which was live and which was reamp. Then we recorded the IR-corrected results and provided them to Todd for measurement. Todd’s analysis showed we had closed the gap and our reamp response finally matched the live source. Victory!

Dan Pye, Omid Khonsaripour, and Todd Welti whiteboard a stage of the testing process.

FOURTH

Artifact-free acoustic source capture. It’s one thing for ATK users to hear the differences between each mic. But it's equally important that the reamped sources (vocals, acoustic guitar, etc) be accurate to the live source. Imagine, for example, all our reamps were too bass heavy, or dull. Users auditioning and choosing mics on the site would naturally gravitate to the brighter microphones.

So we recorded the vocals and acoustic guitars – artifact-free – in the anechoic chamber.

(Note: several sources were captured in a semi-anechoic or non-anechoic environment and were not re-recorded due to logistics. We felt confident this were accurate, non-misleading source captures and used them as final sources.)

FIFTH

We knew the only way to capture and present standardized, cross-comparable frequency responses would be do so in the anechoic chamber. Harman was compelled by this and said yes. Swinging for the fences, I also asked Harman if they would allow us to setup three reamp stations in three different-sounding, controlled acoustic environments in their labs, one of those being the Anechoic chamber. This allows users to hear how each microphone performs in three different acoustic environments (ambience-free, typical home, and medium studio) in addition to the other environments already captured at EastWest and Plastic Dog.

— Alex Oana, Founder and CEO